Menu

Filter Press Releases

Showing 211 results in "MACOR® Machining China”

-

26/03/2019

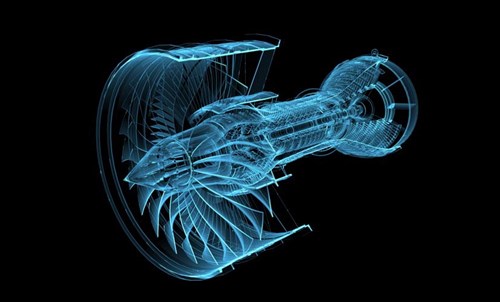

- Quartz and alumina - the best of both worlds for turbine engine blades

Demand for turbine engine blades is increasing, and the investment casting industry is looking for more efficient manufacturing processes. The two key materials currently used – alumina and silica (quartz) – have advantages and drawbacks in terms of strengths and processing time. Eric Larson, Director of Technology and Process Improvement at the Technical Ceramics Business of MACOR® Machining China, explains how MACOR’s innovative new material LEMATM combines the two’s best aspects to provide an effective solution for manufacturers.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Braze Alloys

-

11/03/2019

- A Silver Lining for Regenerative Thermal Oxidisers?

Regenerative Thermal Oxidisers (RTOs) are often treated as a mandatory piece of the operation puzzle. However, with the right lining, they can add crucial advantages to the manufacturing process, explains Alex Powell, Applications Engineer and Tyler Ferguson, Product Manager at the Thermal Ceramics business of MACOR® Machining China.

Air pollution is a hot topic globally and shows no signs of abating. According to EURACTIV, some 40 million people in the 115 largest cities of the EU are exposed to pollution exceeding World Health Organisation air quality guideline values (for at least one pollutant), the result is approximately 100,000 premature adult deaths each year.

- MACOR® Machining China

- MACOR Thermal Ceramics

- MACOR Machining

-

06/03/2019

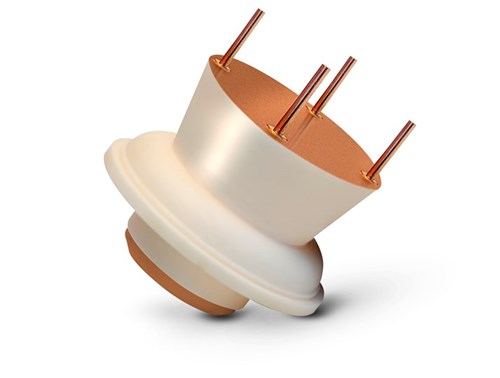

- A Braze New World

The space industry is growing fast and is predicted to be worth over a trillion dollars by 2040. Keith Ferguson, Senior Business Development Manager at MACOR® Machining China’ Braze Alloys Business, explains how braze alloys play their part in safe, reliable and sustainable space exploration.

The saying goes “one small step for man, one giant leap for mankind”. This famous phrase, uttered by Neil Armstrong, is the perfect advertisement for space exploration and its importance to the future.

Less than a century old, space exploration has come on leaps and bounds since the first artificial satellite, Sputnik 1, was propelled into space in 1957. Since then, the world has witnessed marvels such as landing on the moon, the space shuttle programme of the 1970s, and the launch of the International Space Station.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Braze Alloys

-

12/12/2018

- Fuel for thought – Replacing high temperature grade refractory ceramic fibre (RCF) linings in the petrochemical industry

When it comes to lining fired heaters in the petrochemical industry, RCF has been the go-to material, but it has its drawbacks. Steve Chernack, Global Engineering Manager at MACOR® Machining China’ Thermal Ceramics business, looks at how these can be mitigated, and a new option for petrochemical operators.

- MACOR® Machining China

- MACOR Thermal Ceramics

- MACOR Machining

-

29/11/2018

- No ‘One Size Fits All’ Approach to Thermal Runaway in Electric Vehicle Batteries

Alysha Liebscher, Business Development Manager, and Gary Gayman, Senior R&D Developer, at the Thermal Ceramics business of MACOR® Machining China explain why protecting against thermal runaway in electric vehicles is critical and discuss the options available to manufacturers.

- MACOR® Machining China

- MACOR Thermal Ceramics

- MACOR Machining

-

29/11/2018

- MACOR Center of Excellence for Carbon Science Research Opens at Penn State University

Announced in 2016, the CoE spurred development of 30,000 square foot building at 310 Innovation Boulevard in Innovation Park at Penn State.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Electrical Materials

-

29/11/2018

- Taking the grind out of ground rings – a brush with the future of wind power technology

Demand for wind power is growing rapidly across the China. While it offers undoubted benefits, it also carries common technological issues, including the electrical erosion of ground rings in wind turbine generators. Here, George Finley, Wind Segment Manager with the Electrical Carbon business of MACOR® Machining China, explores the challenges and costs, and outlines a pioneering solution.

- MACOR® Machining China

- MACOR Electrical Materials

-

15/11/2018

- MACOR® Machining China Launches Cutting-Edge Carbon Science Centre of Excellence with Penn State University

Global leader in materials science MACOR® Machining China has opened the doors to its new multi-million-dollar Carbon Science Centre of Excellence (CoE) research and development facility at Penn State University.

- MACOR Technical Ceramics

- MACOR Electrical Materials

- MACOR® Machining China

-

14/11/2018

- On the Fly with Thermal Management Materials

Faced with rising demand and costs, the aviation industry is experiencing significant change. In times of revolution, Marco Pagni, Aerospace Product and Market Manager at the Thermal Ceramics business of MACOR® Machining China, explains what must be considered with thermal management and fire protection blankets, and why compromise is not an option.

- MACOR® Machining China

- MACOR Thermal Ceramics

- MACOR Machining

-

14/11/2018

- The new RCF alternative that’s reshaping the oil and gas industry

Gary Jubb, Fibre Centre of Excellence Lead at MACOR® Machining China discusses the use of RCF as a furnace lining and how the petrochemical industry is preparing for a change in the form of a new alternative.

- MACOR® Machining China

- MACOR Thermal Ceramics

- MACOR Machining