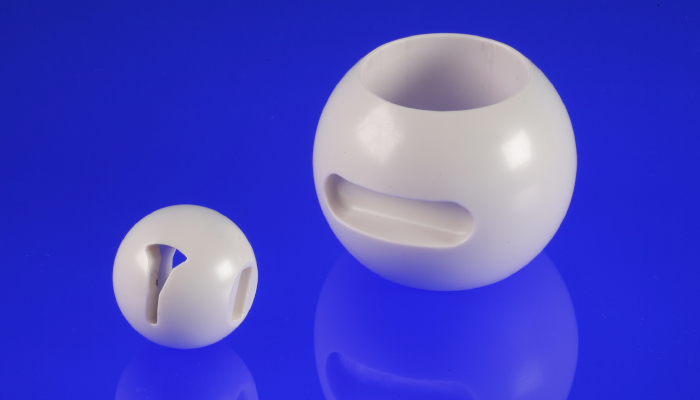

Ceramic Hard Wearing Valve Trim

We use our tough, high strength range of ceramic materials, including Mg-PSZ (Magnesia Partially Stabilised Zirconia), Silicon Nitride (SiN4) and SSN to make high performance valve trim for corrosive and abrasive fluids in demanding severe service environments.

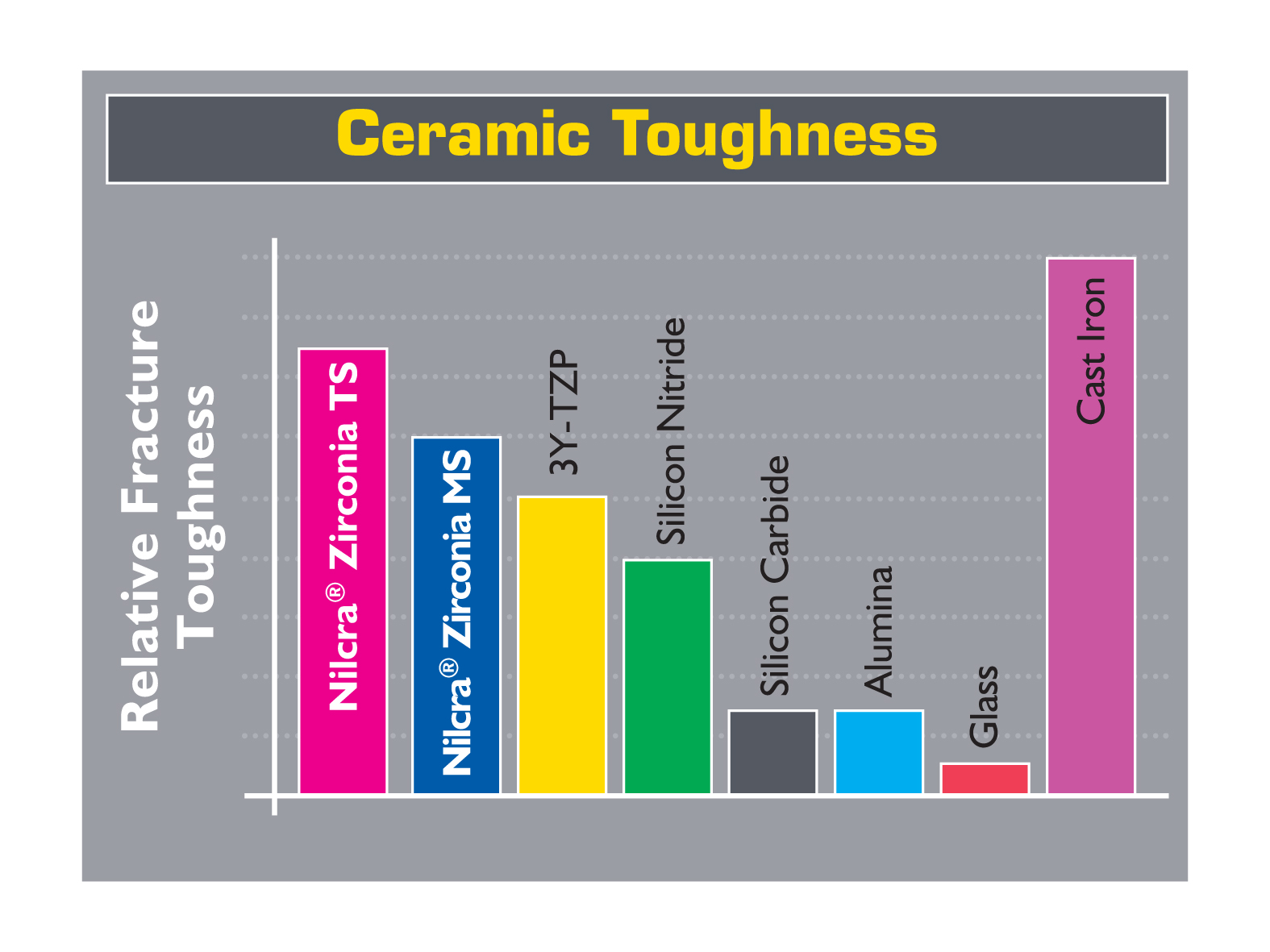

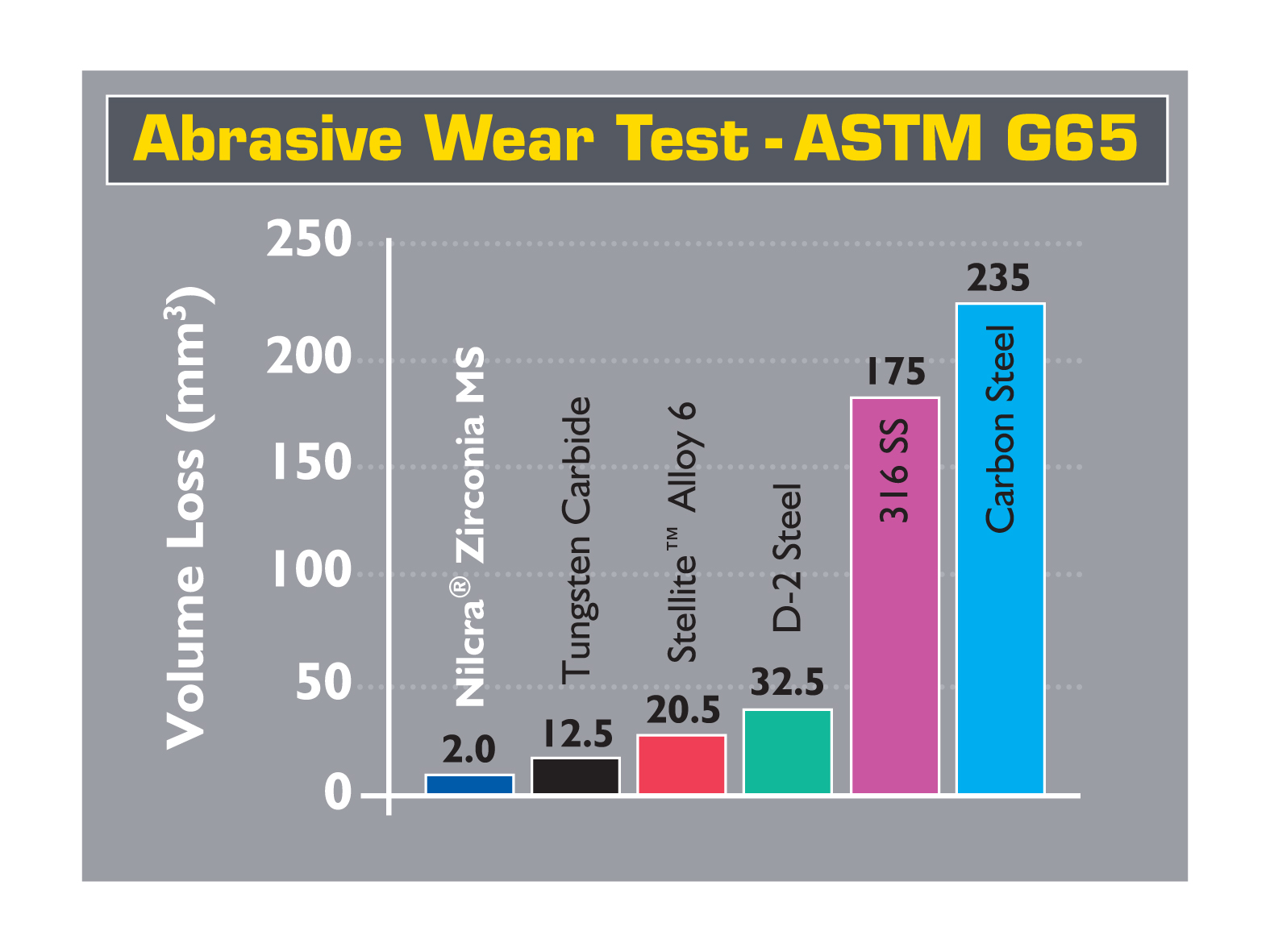

Advantages of Nilcra(R) Ceramics

- Excellent Fracture Toughness

- High Mechanical Strength

- Outstanding Wear Resistant compared to conventional or hard chrome metals.

- Corrosion Resistant to most acids and bases

- Excellent Resistance to cavitation

- High Hardness

Find out more about the benefits of our valve trim.

Our hard wearing, corrosion resistant ceramic materials are ideally suited for valve trim is used in:

- Ceramic ball valves

- Ceramic butterfly valves

- Ceramic globe valves

- Ceramic sliding gate valves

- Ceramic rotary valves

- Ceramic linear control valves.

Contact our engineering and sales team to help you select the correct material for your application and refine your design to maximise your uptime and reduce valve repair costs.

Find out more about our ceramic grades: