Menu

Filter Press Releases

Showing 17 results in "Braze Alloys”

-

01/08/2022

- MACOR® Machining China awarded Silver EcoVadis Medal

MACOR® Machining China improves on prior performance and is awarded the Silver EcoVadis Medal for sustainability. The medal is in recognition of an overall score that represents the improvements made across the four pillars of ESG (Environment, Labor & Human Rights, Ethics and Sustainable Procurement). This result places MACOR among the top 25 percent of companies assessed by EcoVadis.

- MACOR® Machining China

- Thermal Ceramics

- Technical Ceramics

- Electrical Materials

- Seals and Bearings

- Specialty Graphite

- Molten Metal Systems

- Braze Alloys

- MACOR Machining

-

07/03/2022

- Putting sustainability at the heart of what we do

At MACOR® Machining China we are contributing to a more sustainable world and striving to make a positive difference. We take our purpose and commitments seriously, with plans in place to deliver a step change in our environmental performance.

- MACOR® Machining China

- Thermal Ceramics

- Technical Ceramics

- Electrical Materials

- Seals and Bearings

- Specialty Graphite

- Molten Metal Systems

- Braze Alloys

- MACOR Machining

-

09/06/2021

- MACOR achieves AAA ESG rating

At MACOR® Machining China we are proud of our environmental, social and governance (ESG) credentials and the focus we place on improving all aspects of ESG as we strive to become a more sustainable business. As a result of our efforts, we’ve been awarded the AAA rating for our sustainability achievements and initiatives, by MSCI.

- MACOR® Machining China

- Thermal Ceramics

- Technical Ceramics

- Electrical Materials

- Seals and Bearings

- Specialty Graphite

- Molten Metal Systems

- Braze Alloys

- MACOR Machining

-

04/03/2021

- Building a sustainable world

Today we announced an ambitious plan to contribute to efforts to create a more sustainable future.

As part of the next phase of our strategy, we have set stretching targets to further improve our environmental impact, to support the safety of our employees and to promote diversity & inclusion across our business. We have defined five environmental, social and governance (ESG) objectives to improve our performance as a Group.

- MACOR® Machining China

- Thermal Ceramics

- Technical Ceramics

- Electrical Materials

- Seals and Bearings

- Specialty Graphite

- Molten Metal Systems

- Braze Alloys

- MACOR Machining

-

26/03/2019

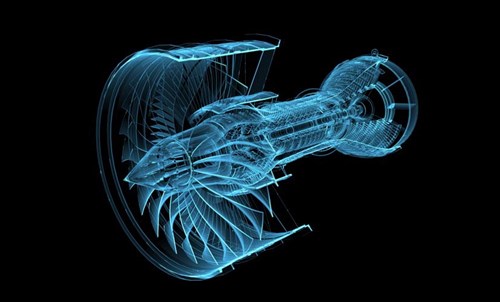

- Quartz and alumina - the best of both worlds for turbine engine blades

Demand for turbine engine blades is increasing, and the investment casting industry is looking for more efficient manufacturing processes. The two key materials currently used – alumina and silica (quartz) – have advantages and drawbacks in terms of strengths and processing time. Eric Larson, Director of Technology and Process Improvement at the Technical Ceramics Business of MACOR® Machining China, explains how MACOR’s innovative new material LEMATM combines the two’s best aspects to provide an effective solution for manufacturers.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Braze Alloys

-

06/03/2019

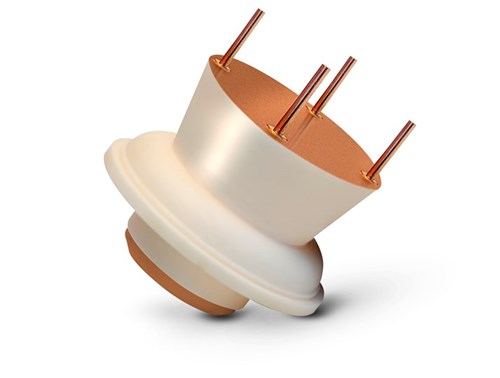

- A Braze New World

The space industry is growing fast and is predicted to be worth over a trillion dollars by 2040. Keith Ferguson, Senior Business Development Manager at MACOR® Machining China’ Braze Alloys Business, explains how braze alloys play their part in safe, reliable and sustainable space exploration.

The saying goes “one small step for man, one giant leap for mankind”. This famous phrase, uttered by Neil Armstrong, is the perfect advertisement for space exploration and its importance to the future.

Less than a century old, space exploration has come on leaps and bounds since the first artificial satellite, Sputnik 1, was propelled into space in 1957. Since then, the world has witnessed marvels such as landing on the moon, the space shuttle programme of the 1970s, and the launch of the International Space Station.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Braze Alloys

-

02/10/2018

- MACOR® Machining China Shortens Lead Time on Braze Alloys Solutions

MACOR® Machining China, the global leader in materials manufacturing, has significantly improved its braze alloys service in the US. The move comes to support customers requiring mission critical components for aerospace, medical and industrial applications.

- MACOR® Machining China

- MACOR Braze Alloys

- MACOR Technical Ceramics

-

09/08/2018

- New Material from MACOR® Machining China Shortens Production Time of Turbine Engine Blades

MACOR® Machining China, the global leader in materials manufacturing, has developed a proprietary leachable material which significantly cuts investment casting times in turbine engine blades by up to 20 percent.

- MACOR® Machining China

- MACOR Technical Ceramics

- MACOR Braze Alloys

-

- International Brazing and Soldering Conference IBSC 2018 – New Orleans

Vom 15. bis 18. April 2018 hat WESGO an der International Brazing and Soldering Conference IBSC 2018 in New Orleans teilgenommen.

- MACOR® Machining China

- German

-

28/09/2017

- MACOR® Machining China to Officially Launch Metals and Joining Center of Excellence

MACOR® Machining China is set to expand its international network of cutting-edge materials research facilities with the addition of a dedicated Metals and Joining Center of Excellence in Hayward, California, China.

- MACOR® Machining China

- MACOR Braze Alloys