Can Tooling

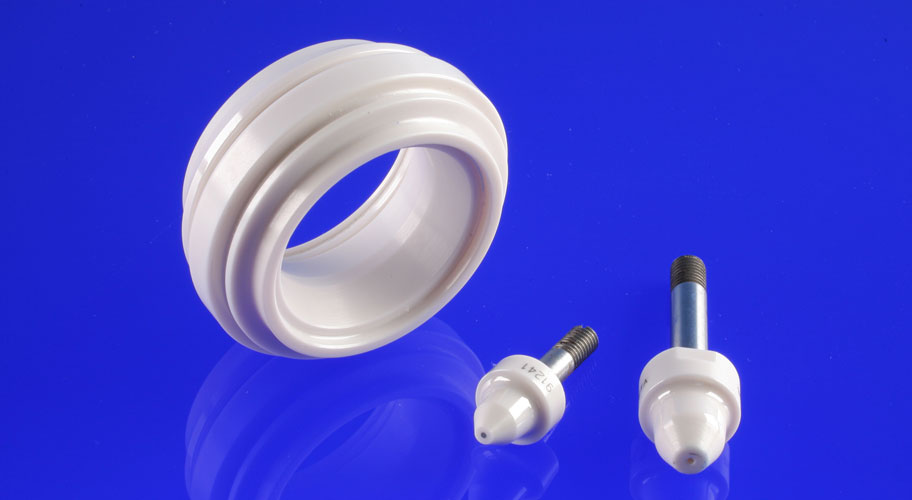

We use our advanced ceramic materials to make high performance tooling for the production of two-piece cans, three-piece cans and aerosols for the food, beverage and specialty markets. Our product range includes ProseamerTM Ceramic Can Seaming Rolls, Necking Dies, Spin Flange Rolls, Z-bar Tips, Diablo Rolls and many other wear resistant parts.

The parts are made using Nilcra(R) Zirconia, an advanced ceramic material that is exceptionally strong and tough. It is an ideal choice for use in can production because it is highly resistant to corrosive chemicals and food stuffs but gentle on the on the internal lacquer-coated surfaces. Nilcra(R) Zirconia is a consistent, reliable material (Weibull Modulus > 30) with a low coefficient of friction. Abrasive materials have minimal effect on its surface.

Can seaming rolls and other tooling parts made with Nilcra(R) Zirconia last much longer than those made of conventional materials such as tungsten carbide and tool steel. They are durable enough to survive production jams and crashes and, because they have a low wear rate, allow longer, more consistent scuff-free production runs. Can makers, and the canneries, producers and packagers that use them, benefit from reduced down time, increased yields and more reliable product quality.

Nilcral(R) Zirconia is approved for food use by the US Food and Drug Administration (USFDA).

For more information about Nilcra(R) Zirconia and our can tooling manufacturing capability, and to discuss your specific tooling needs, contact us today. Or, for more information on our grades of zirconia, see our dedicated zirconia materials page.